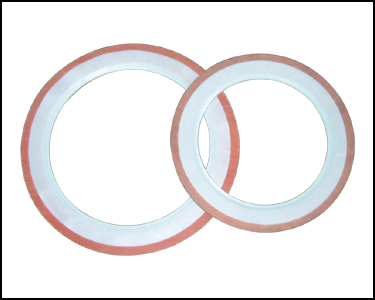

| PTFE coating gasket

PTFE coating gasket is a kind of nonmetal gasket. Generally it consists of two parts: coating and insert. The coating is made of PTFE, mainly for corrosion resistance; while the insert (packing) is made of a flexible non-metal sealing material with or without the metal reinforcing layer, which is paronite in general. According to different structures of its inner core, the gasket with this density can be divided into such types as V, U and L. Also it is often used as a sealing element for the connection of some containers, pipelines and valves in such industries as petroleum, chemical industry, pharmacy and food to guarantee the cleanness of materials. It is widely applied for the sealing of different kinds of strong acid, alkali and oxidization, chlorine and media with no pollution allowed.

Model and structure:

| Structural diagram |

Designation |

|

V-shape, namely the Teflon pad is cut from outside to inside |

|

U-shape, namely the Teflon band is wrapped and then bonded through heating |

|

L-shape, namely the Teflon rod is machined and turned | |

Scope of application:

| Pad material |

Structural diagram |

Temperature℃ |

Pressure(Mpa) |

| Asbestos composite board |

|

150 |

1 |

| Non-asbestos composite board |

|

200 |

2 |

Add one layer of asbestos board between

two layers of asbestos extracting board |

|

220 |

2.5 |

Add one layer of non-asbestos board between

two layers of non-asbestos extracting board |

|

220 |

2.5 | |

Key technical parameter of Teflon cladding pad:

| Pressure |

≤4.0MPa |

| Temperature |

≤260℃ |

| Pad coefficient |

m=2.5 |

| PH |

0-14 |

| Min. pretension specific pressure |

y=20MPa | |